PET bottle washing recycling machine

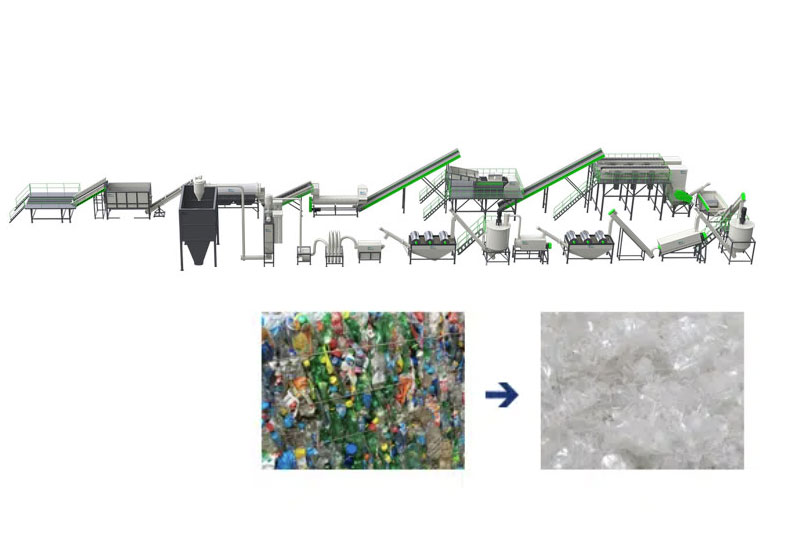

PET bottle washing recycling machinery is widely used for waste PET bottle. It includes de-label machine, feeder, crushing and washing machine, steaming washing, floating tank, drying and storage silo.Finally product is the cleaned PET Flakes. We can also provide a variety of personalized design solutions. Production capacity is from 500 kg/h to 2000kg/h.

PET bottle washing recycling machine description

Ableplas PET bottle recycling Machinery production line is suitable for all kinds of PET bottles recycling, like mineral water bottle, sodas bottles etc. The whole line includes bale opener, label remover, manual sorting, crushing, hot steaming, floating tank washing, drying and silo system. Different scheme could be offered according to material’s condition.

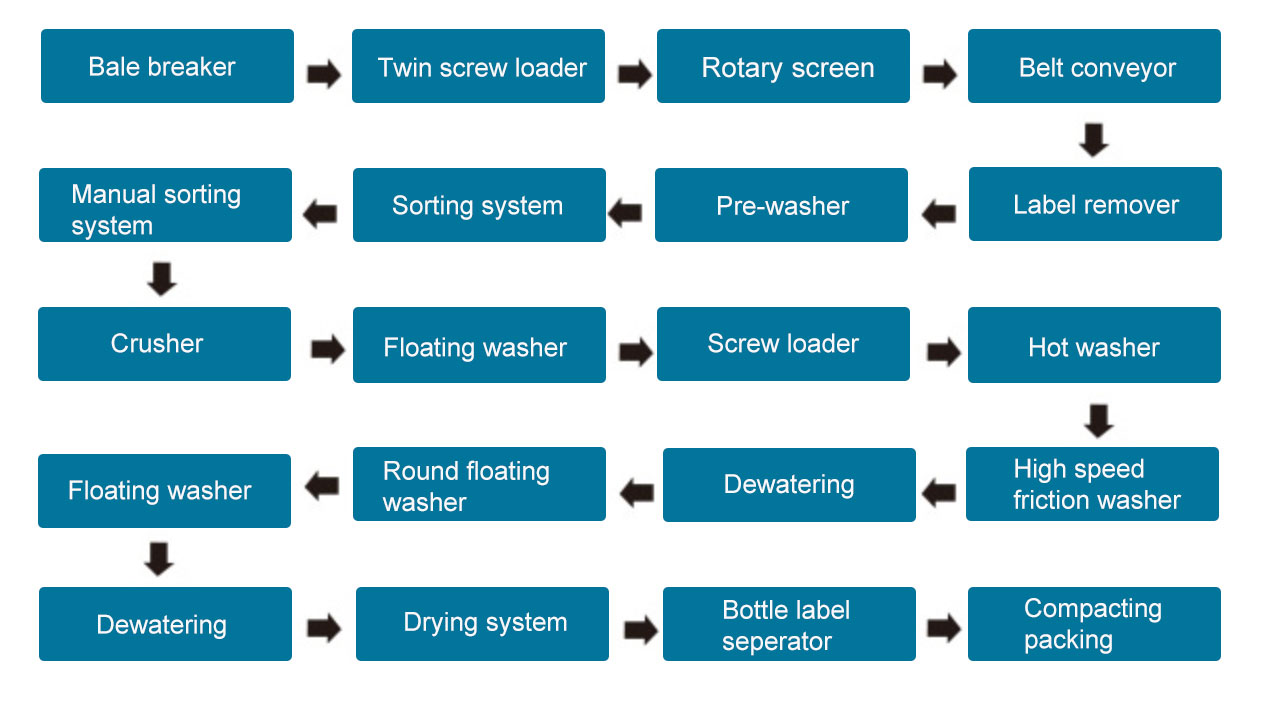

Ableplas Plastic Bottle Recycling Washing Machine Work Process:

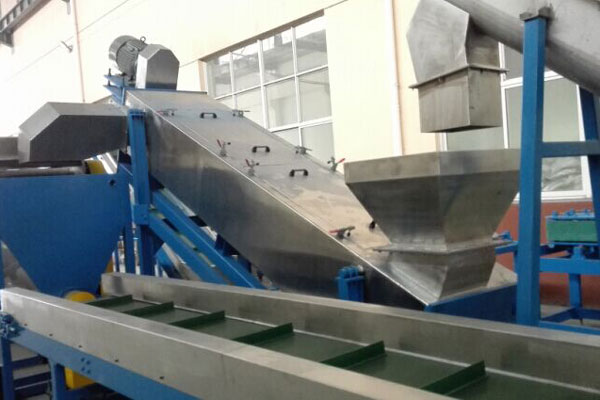

Belt conveyor:

The belt conveyor is for transporting all kinds of plastic bottles to crusher, it is automatically working. Frequency control.

Bale breaker

The bale breaker is used for openning the PET bottles’ bale before crushing and washing.

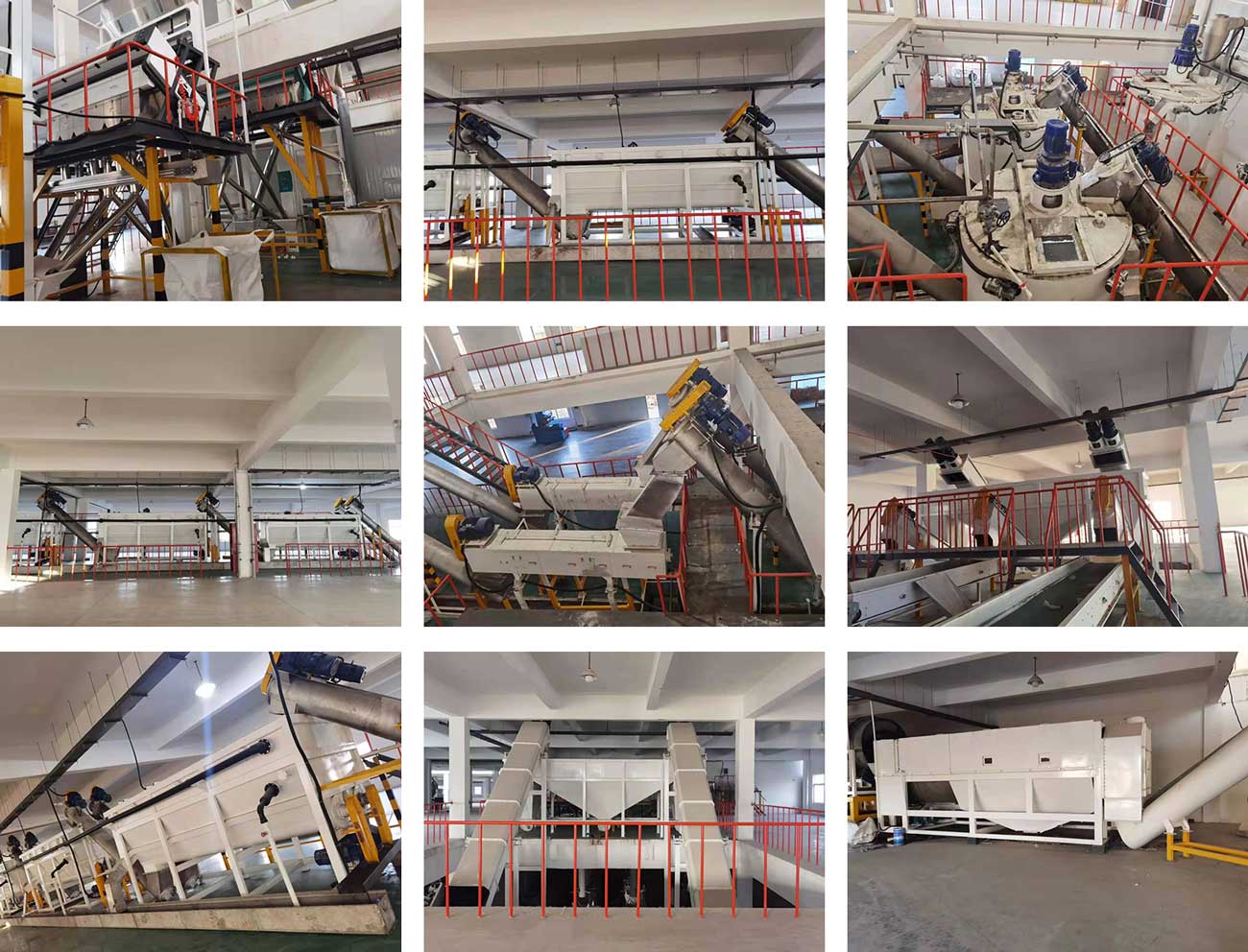

Crusher

The crusher will crush PE film into small sizes. Large PE Film will reduced into small pieces.

Label remover

The label remover can remove the plastic label by using the air suction and blade friction .

This machine is mainly used to remove the PVC label and OPP label and other label from the bottle.

Floating Washer

The floating washer can seperate the metal and washing the crushed PE film. Parts touch with materials made by stainless steel.

Dewatering Machine

The dewatering machine will shake off the film moisture. Dewater effective : ≧95%

Cleaning line diagram